What is Electric Arc Wire Spraying?

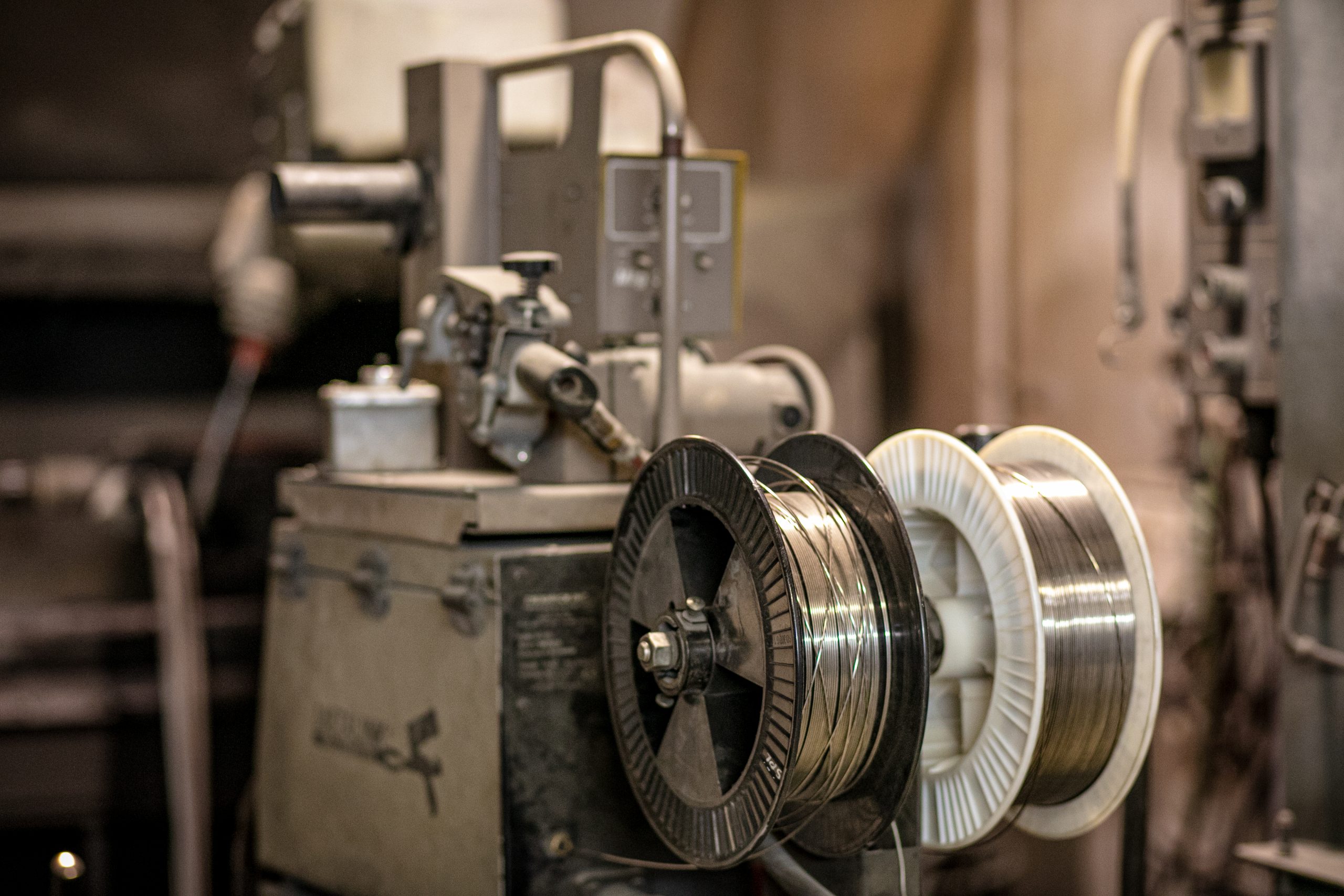

By definition, arc spraying is a thermal spray process wherein molten droplets are sprayed onto a substrate to form an interlocking surface deposit. In arc spraying, two consumable wire electrodes are used to form the electric arc. The heat of the electric arc melts the metal of the wire electrodes, and the resulting molten droplets are sprayed onto the substrate by a gas jet immediately behind the arc zone. The arc spray process is often used to apply coatings of zinc, aluminum, or other metals onto metallic substrates. The deposited metal coatings provide corrosion resistance and wear resistance properties.

Protecting your place of business is important. Electric arc wire spraying offers a high-quality, long-lasting solution for a variety of needs.

Have you ever wondered how those big, metal sculptures get their smooth, shiny finish? Or how buildings are coated with a protective layer to prevent corrosion? Electric arc wire spraying is a process that can be used to apply these types of finishes.

In electric arc wire spraying, an electric arc is used to melt a metal wire. The molten metal is then sprayed onto the surface that needs to be coated. This process can be used to apply a variety of metals, including zinc, aluminum, and stainless steel.

Common Applications

Aside from HVAF spray coating, arc wire spray coating can be used to apply thermal barrier coatings to jet engine parts, wear-resistant coatings to machinery, and corrosion-resistant coatings to steel structures.

Electric arc spraying is a thermal spraying process that uses an electric arc to heat and melt metal wires. The molten metal is then sprayed onto the surface of the workpiece. This type of flame spraying can be used to coat metals, ceramics, and even plastics with a wide range of material types.

Furthermore, the electric arc spraying process is commonly used in the aerospace, automotive, and energy industries due to its ability to provide a high-quality, durable coating.

SUMMARY

Electric arc spraying is a thermal spraying process that uses an electric arc between two consumable electrodes of the surfacing materials as the heat source.

Contact Wear Master

If you are looking for a thermal spraying process that can provide a high-quality, durable coating, electric arc wire spraying is an excellent option. Now, if you’re looking for the right company to call for Electric Arc Wire Spray TX, look no further than Wear Master.

With years of experience in the thermal spraying industry, Wear Master has the knowledge and expertise to provide you with the best electric arc wire spraying services possible. So, if you’re in need of electric arc wire spraying services, don’t hesitate to contact Wear Master today.

Electric Arc Wire Spraying Advantages

There are a number of advantages that electric arc wire spray has over other thermal arc spray coatings.

Electric arc wire spraying can be used to coat a wide range of materials, including metals, ceramics, and plastics. The molten material used in electric arc wire spraying can also be utilized to coat surfaces with difficult-to-bond materials, such as aluminum oxide.

This type of thermal arc spraying process is also much faster than other methods, such as plasma spraying and other HVOF coating services because it does not require a preheat step.

Electric arc wire spraying can also be used to coat large areas with a uniform coating thickness along with a highly versatile thermal spraying process that can be used in a wide range of applications.

In addition, twin wire arc spraying offers a higher deposition rate than other thermal spray processes because two wires are melted simultaneously.

Electric Arc Spray Process Parameters

Electric Arc Spray Process Parameters

Just like any other spraying method, there are a few process parameters that need to be taken into account when using electric arc wire spraying.

Some of the most important electric arc wire spray process parameters include wire feed rate where the faster the wire feed rate, the thicker the sprayed coating.

The arc current is also an important parameter as it controls the heat input into the wire. The higher the arc current, the hotter the wire will get, and the more molten material will be deposited onto the surface.

Aside from these two, the spray distance is also an important electric arc wire spray process parameter that one should consider as it determines the amount of material that is deposited onto the surface.

Arc Wire Thermal Spray Experts

If you need arc wire for your next thermal spray application, look no further than Wear Master. Our solutions-based expert team of craftsmen and technicians will work with you to find the best solutions that affect your parts. Contact Wear Master today to schedule a free consultation.

FAQ

WHAT IS ARC SPRAY COATING?

Arc spray coating is a thermal spraying process that uses an electric arc to heat and melt metal wires. The molten metal is then sprayed onto the surfacing materials. The heat source in arc spray coating is an electric arc between two consumable metal wires. The heat from the arc melts the wire, and the force of the compressed gas propels the molten droplets onto the surface.

WHAT IS THERMAL SPRAY WIRE?

Electric arc wire spraying utilizes a particular type of metal wire known as thermal spray wire. An electric arc heats and ultimately melts the wire. The workpiece’s surface is subsequently sprayed with molten metal.

WHAT IS ARC WIRE?

Arc wires are types of metallic wires that are also used in the electric arc wire spraying process. You could see arc wire in other applications such as welding where an electric arc is used to heat the wire until it’s molten. In electric arc wire spraying, the molten metal is then sprayed onto the surface of the material.

Table of Contents

- 1 What is Electric Arc Wire Spraying?

- 2 Common Applications

- 3 Contact Wear Master

- 4 Electric Arc Wire Spraying Advantages

- 5 Electric Arc Spray Process Parameters

- 6 FAQ

- 7 How to Choose the Right Thermal Spray Company in TX for Your Project

- 8 Protect Your Aircraft: The Power of Aerospace Thermal Coatings

- 9 Metal Spray Coating