Thermal Spray for Aerospace Industry

What is Thermal Spray Coating?

Thermal spray coating is a technique for improving or restoring the surface of a material from natural wear, erosion, cavitation, corrosion, abrasion, and more.

It is used in a variety of industries, including aerospace and automotive. Thermal spray coatings can be applied in a number of different ways, depending on the desired results.

How Thermal Spray Coating Works

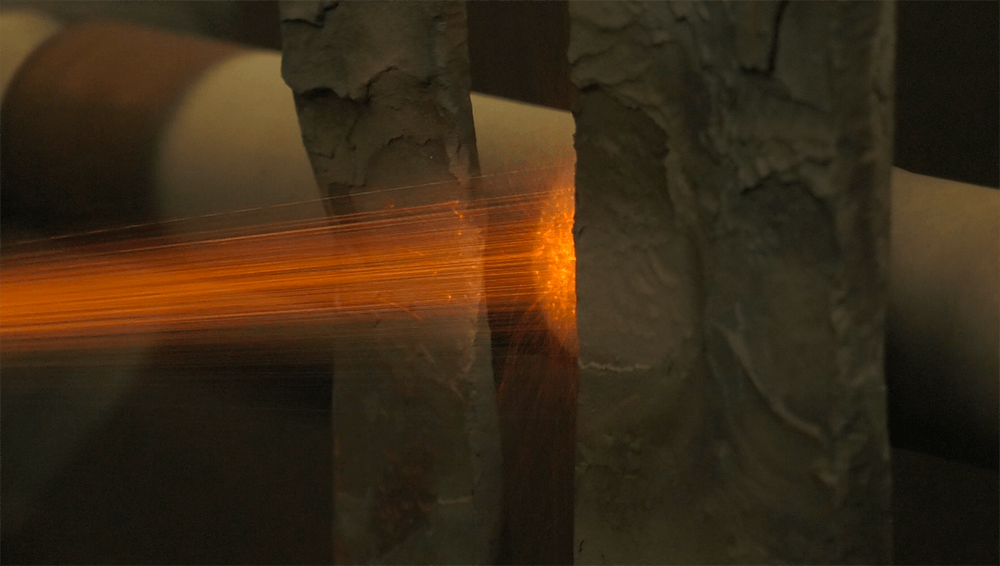

Thermal spray coating is the application of hot metals, alloys, ceramics, composites, and polymers to a surface.

The liquid is then mixed with these components and heated until the mixture is half-liquid. Thousands of tiny, individual droplets are then sprayed at a high speed toward a surface in the form of a wire or powder.

How Are Thermal Spray Coatings Used in the Aerospace Industry?

Thermal spray coatings are used in the aerospace sector to safeguard components from the high temperatures and extreme conditions encountered during flight.

Engine turbine blades, for instance, are protected from extreme temperatures with thermal spray coatings, which ensure increased reliability for extended periods. These coatings are replacing hard chromium plating in landing-gear applications as the preferred technique to improve performance.

There are several types of aerospace thermal spray coatings that are used in the aerospace industry as coating solutions, including:

Combustion Flame Spraying

Combustion flame spraying is a suitable choice for materials that are not designed to withstand extreme strain.

Because the spraying mechanism is driven by a slower flame speed, the coating formed as a result of this technique is not particularly firmly bonded to the surfaces.

The combustion flame will be produced by combining oxygen with the fuel in the mixture, resulting in it melting. Combustion flame spraying is considered cost-effective for low-intensity applications.

Advantages

- It can be carried easily and is simple to use

- It is cost-effective

Disadvantages

- Lower-quality coatings

- Restricted areas are difficult to coat

Thermal Barrier Coatings

Thermal barrier coatings are typically used as a light film on the surface of a component. They are used to prevent metal components from oxidation and corrosion. Heat transfer from the part to the surrounding environment can be reduced by using the thermal barrier coating.

Advantages

- Extend component life of critical parts

- There are a variety of coating materials available

Disadvantages

- Impossible to distinguish what is the substrate is made of

- May need expensive equipment.

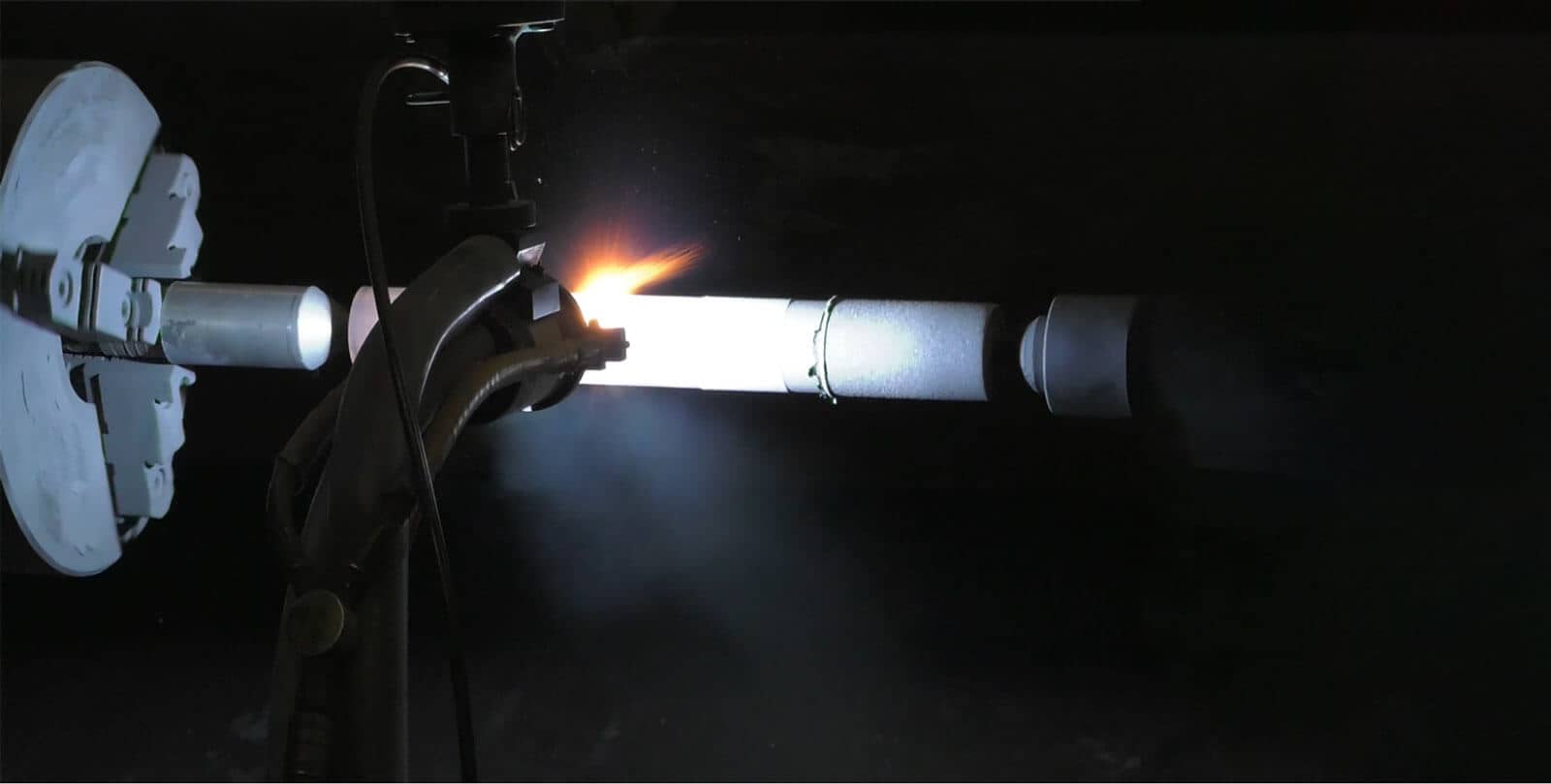

HVOF (High-Velocity Oxy-Fuel Spraying)

The HVOF technique also known as “torch dipping” recently replaced hard chrome plating as the preferred method of coating solutions.

HVOF is a process that utilizes a torch with a flame that spreads when the nozzle is used. This results in rapid particle acceleration, which speeds up the mixture’s particles. An extremely thin covering is formed as a result of this process. Despite its thinness, this coating is robust and adheres well.

Advantages

- As a result of less carbide phase deterioration, the harder, tougher coatings have increased wear resistance.

- Lower compressive stress results in thicker coatings being able to be applied.

- Improved cohesive strength and durability within the coating and a stronger bond to the underlying substrate.

- This method produces sturdier and smoother coatings since the impact speed is higher.

Disadvantages

- HVOF is not appropriate for coating interior, or other restricted access surfaces since HVOF spraying line of sight to the surface and a spray distance of 150-300 mm.

- Due to the many variables in the technique, HVOF sprayed coatings may be quite complicated.

- When compared to the electric arc spraying or flame spraying processes, HVOF spraying is more expensive due to the equipment required for its operation.

Plasma Spraying

The plasma torch is utilized as the major tool for heating and spraying the coating in this sort of thermal spray.

The powder material is then melted down and placed on the product, which is similar to combustion flame spraying after that. The coatings generated by plasma spraying can range from a few micrometers to a few millimeters thick.

Metals and ceramics are both utilized in powder form, which is the most common material used. Due to its flexibility, the plasma spraying technique is very popular.

Advantages

- Plasma spray coatings, when compared to other traditional thermal techniques such as flame spraying, have a higher quality.

- A wide range of coatings (in powdered form) may be produced to meet a wide range of requirements.

Disadvantages

- Automated gun manipulators are required for plasma spraying. Manually operating a machine is not suitable.

- It’s difficult to coat restricted access surfaces and tiny internal bores since they are a line-of-sight operation.

Frequently Ask Questions (FAQs)

What materials can be subjected to thermal spray?

A wide range of materials can be subjected to thermal spraying such as:

- nickel alloy

- stainless alloy

- steel,

- carbides

- copper

- bronze

What are some common applications of thermally sprayed coatings?

- Wear and abrasion resistance coatings – mining

- Biomedical – orthopedics (e.g. hydroxyapatite), dentistry, cancer therapy

- Thermal barrier coatings – combustion engines

- Abradables – aerospace industry

- Electronic applications

How many coatings of thermal spray are needed?

The number of coatings that are needed is dependent on the substrate and the application.

Generally, two to three coats are recommended. However, more may be necessary in some cases. Thermal barrier coatings (TBCs) are generally applied in multiple layers to achieve the required thermal and mechanical properties.