Choosing the Best Thermal Spray Companies TX: A Buyer’s Guide

Selecting the right thermal spray company in Texas is important if you want to ensure the longevity and performance of your industrial equipment.

That’s why we made this guide to help you simplify decision-making by highlighting the key factors to consider when choosing a thermal spray provider.

Understanding what leading companies offer will help you make an informed choice for your needs, whether you’re looking for innovative solutions for thermal spray coatings or expertise in specific applications.

Understanding Thermal Spray Coatings

Thermal spray coatings are a group of techniques used to apply a material onto a surface in a molten or semi-molten state to form a coating that enhances the performance and longevity of the underlying material.

Thermal spray processes are used in various industries, such as the following:

- Aerospace: Used on turbine blades, engine components, and aircraft structures to improve wear resistance, corrosion protection, and thermal insulation.

- Automotive: Applied to engine components, exhaust systems, and brake rotors to enhance durability, heat resistance, and noise reduction.

- Energy: Coatings for power plant components, boilers, and turbines to improve efficiency, corrosion resistance, and heat transfer.

As a versatile and adaptable solution, thermal spray coating continues to drive innovation and performance improvements across numerous applications.

What Are Thermal Spray Coatings?

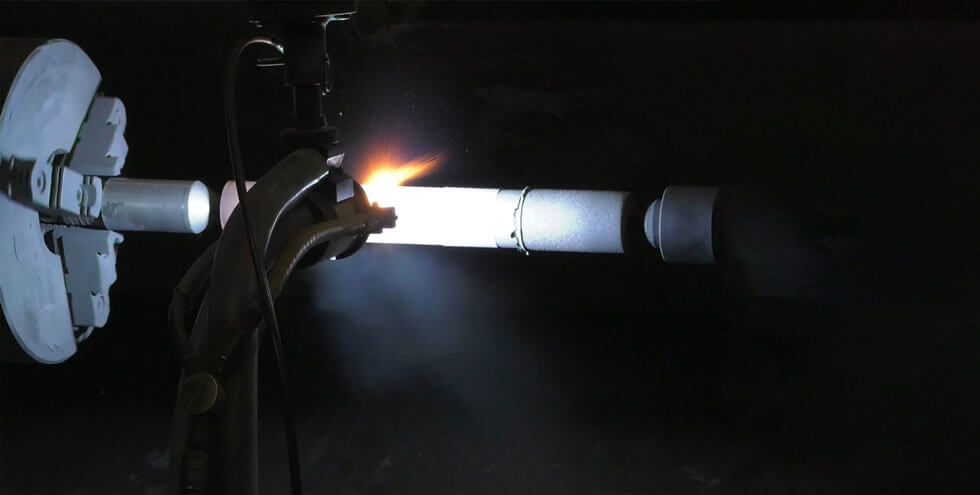

Thermal spraying is a process that applies a protective layer to a substrate or the base. This thermal spray process uses the power of heat to melt or heat coating materials, creating a fine spray that is then propelled onto the substrate.

In the thermal spray coating application, heat is used in the following ways:

- Material Heating: The coating material is heated to a high temperature, often using a plasma spray, flame spray gun, or detonation gun.

- Material Spraying: When the heated molten material is sprayed onto the substrate, the high kinetic energy of the particles helps them to bond upon impact.

Enhancing Durability Through Heat

- Creates Strong Bonds: The heat energy provided during the process creates strong bonds between the coating particles and the substrate, enhancing the durability and adhesion of the coating.

- Improves Material Properties: The high temperatures involved in the process can alter the properties of the coating material, such as hardness, wear resistance, and corrosion resistance.

- Protects The Base Material: The thermal spray coating material acts as a protective barrier that shields the substrate from environmental factors such as wear, corrosion, and high temperatures.

Key Applications and Benefits

Thermal spray coatings are integral across a wide range of industries, offering solutions that cater to various needs:

Aerospace

Utilized extensively on turbine blades, landing gear, and other critical components to resist wear and erosion, ensuring reliable performance in harsh environments.

Automotive

Applied to pistons, cylinders, and crankshafts to reduce friction, resulting in smoother operations and extended engine life.

Oil and Gas

Protects pipelines, valves, and pumps from extreme conditions by providing robust corrosion resistance, enhancing the safety and reliability of equipment.

Medical

Used on surgical instruments and implants for better wear resistance and biocompatibility for the safety and longevity of medical devices.

Visit our page to learn more about comprehensive insights on applications and thermal spray coating services.

Criteria for Selecting Thermal Spray Companies TX

When choosing thermal spray coating experts in Texas, several important factors should be considered to ensure quality and reliable service.

These include:

- Expertise and Experience: Demonstrates a commitment to excellence and the ability to handle complex projects.

- Range of Thermal Spray Services: A comprehensive suite of thermal spray solutions tailored to various industrial needs indicates a versatile and proficient provider.

- Quality Certifications: Reflects a dedication to maintaining high quality and industry compliance.

- Customer service support: Good communication and responsive service ensure that your needs are met efficiently and effectively.

Specialized Knowledge and Experience

In the field of thermal spray coatings, specialized knowledge, and industry experience are crucial factors in delivering high-quality results.

It’s companies with a deep understanding of thermal spraying techniques, materials, and applications that can offer significant advantages to their clients.

Here’s why specialized knowledge and experience matter:

Tailored Solutions

Companies with in-depth knowledge of thermal spray and coating processes can provide tailored solutions that meet specific application requirements. They can select the most suitable thermal barrier coatings, optimize process parameters, and ensure the coating’s performance aligns with the client’s needs.

Problem-Solving Expertise

Experienced companies know how to effectively address challenges that may arise during the coating process by leveraging their expertise to find efficient solutions.

Quality Assurance

Companies with specialized knowledge and experience have a deep understanding of the factors that can affect coating quality and can take proactive steps to prevent defects to ensure the coating meets or exceeds industry standards.

Cost-Effective Solutions

Experienced companies can help you achieve cost-effective solutions by optimizing processes and selecting the right materials. They can identify opportunities for process improvements and minimize waste, leading to lower overall costs.

Range of Services Offered

To cater to a client’s varying needs, thermal spray companies should offer a diverse range of services.

A wider range of services indicates the company’s versatility and ability to meet the unique requirements of different industries and applications.

Listed below are some essential services that thermal spray companies should provide:

- Component Coating: This involves applying thermal spray coatings like metallic or ceramic coatings to various components to enhance their durability, corrosion resistance, and other properties.

- Surface Restoration: Uses thermal spray to restore worn or damaged surfaces, extending the lifespan of components and reducing the need for costly replacements.

- Functional Coatings: Applied to create coatings with specific functional properties, such as electrical conductivity, thermal insulation, or wear resistance.

- Repair Services: Repair services for existing coatings, including re-coating, surface preparation, and defect rectification.

- Customization and Prototyping: Customized coating processes and materials for specific customer requirements. Prototyping services can help clients evaluate different coating options before making final decisions.

- Consultation and Engineering Support: Offering consultation and engineering support can help clients identify the most suitable thermal spray solution for their needs.

- Quality Control and Testing: Robust quality control measures ensure that coatings meet the desired specifications. This includes testing for properties such as hardness, thickness, and adhesion.

Evaluating Quality and Technology

Evaluating the quality and technology employed by thermal spray companies is critical to ensure the coatings meet industry standards.

A comprehensive assessment involves several key aspects:

- Advanced Equipment and Techniques: Using state-of-the-art spraying equipment and the latest technological advancements for higher-quality coatings.

- Comprehensive Testing and Quality Control: Rigorous quality control measures ensure that the products perform reliably under various conditions.

- Intellectual Property and Patents: Companies with patented technologies demonstrate a commitment to unique, innovative approaches.

Understanding these aspects ensures that you receive services and products that are not only effective but also align with your business needs, ultimately enhancing the performance and longevity of the components.

Innovative Techniques Used by Leading Thermal Spray Companies

Innovation is a driving force in the thermal spray coatings industry, enabling companies to achieve better results, improve efficiency, and stay ahead of the competition.

Some of the key innovative techniques are:

- Hybrid Coating Processes: This combines different thermal spray techniques, such as plasma spraying and detonation spraying to create coatings with unique properties and enhanced performance.

- Nanostructured Coatings: Coatings with nanoscale structures can lead to improved properties, such as increased hardness, wear resistance, and corrosion protection.

- Intelligent Coatings: Incorporating sensors or other functional elements into coatings allows them to monitor their own performance, adapt to changing conditions, or even self-heal.

Embracing advanced techniques and technologies pushes the boundaries of what is possible in this field.

Top companies are actively investing in research and development to explore and implement innovative techniques like developing new coating materials, optimizing the coating process, implementing automation, and more.

Certifications and Standards Compliance

Certifications and compliance with industry standards are paramount in the world of thermal spray services. These indicators validate a company’s expertise and also show its commitment to delivering high-quality, safe, and reliable services.

This benefits the company in different ways:

- Enhanced Reputation: A company with certifications and is compliant with industry standards can build a strong reputation in the market.

- Improved Customer Satisfaction: Clients are more likely to be satisfied with the services provided by a company that shows a commitment to quality and safety.

- Competitive Advantage: Companies with certifications and meet industry standards have a competitive edge. It differentiates them from others in the industry especially those without certifications.

Why Choose Wear Master

Of all the thermal spray companies in Texas, Wear Master stands out as a top choice thanks to our unwavering commitment to quality, reliability, and industry expertise.

We’ve built a robust reputation with years of delivering exceptional service and utilizing advanced equipment and cutting-edge technologies. This ensures that every coating meets the highest industry standards.

We have experienced professionals with deep technical knowledge and a keen understanding of various applications. Plus, our rigorous quality control and testing processes ensure that our coatings perform consistently under challenging conditions.

Overview of Wear Master’s Services and Specialties

At Wear Master, we offer a comprehensive range of services tailored to meet your various needs for thermal spray coating services.

Plasma Spray Coating

This process involves melting powders and spraying them onto a surface using a high-temperature plasma flame made from inert gases.

It’s a versatile method that can be used to coat a variety of materials, including metals, ceramics, and even aircraft components.

Best for: Protecting surfaces from wear, heat, and corrosion.

HVOF Coating

HVOF (High-Velocity Oxy-Fuel) coating uses a very high-speed flame to create coatings that are dense, hard, and strongly bonded to the surface.

Unlike other thermal spray processes, HVOF coatings often don’t need a special bonding layer and can be applied directly on top of existing coatings.

Best for: Protecting various components from wear and tear.

Electric Arc Wire Spray

This method involves using an electric arc gun to melt two wires and spray the molten material onto a surface. This method is known for its affordability and durability, with slightly stronger bonds compared to combustion thermal spray coatings.

Best for: Lower cost method without sacrificing durability.

Visit our page now for more detailed information on our services.

Conclusion and Next Steps

Selecting the right thermal spray company is crucial to ensuring that components are protected with top-tier, long-lasting coatings.

Evaluating quality and technology, the implementation of innovative techniques, and the significance of certifications and standards compliance are all important factors that can impact your decision.

Making an Informed Decision

This guide has provided all the information needed when selecting a thermal spray company. Here are some tips to help you navigate the selection process:

- Conduct Thorough Research: Review multiple companies and compare their offerings. Look for those with a robust presence in the industry, testimonials, and case studies.

- Evaluate Certifications and Standards Compliance: Certifications and compliance with industry standards demonstrate their commitment to quality and safety.

- Consider Technological Advancements: Opt for companies that embrace innovation. A company that invests in R&D is likely committed to delivering top-tier solutions.

- Balance Cost with Value: Consider the long-term value of high-quality coatings that offer durability and protection. Cheaper options may result in higher long-term costs due to frequent maintenance or replacements.

Get in Touch with Wear Master

Whether you’re seeking more information or are ready to request thermal spray services, Wear Master is here to assist you every step of the way.

Our dedicated team of experts is ready to answer any questions you may have and provide tailored solutions that your business demands while delivering exceptional quality and customer satisfaction.

Contact us and take the first step towards ensuring exceptional thermal spray solutions that will help your business succeed!

Table of Contents

- 1 Understanding Thermal Spray Coatings

- 2 Criteria for Selecting Thermal Spray Companies TX

- 3 Evaluating Quality and Technology

- 4 Why Choose Wear Master

- 5 Conclusion and Next Steps

- 6 Thermal Spray Coating Services in TX: The Key to Reducing Equipment Downtime

- 7 Why Should You Use Plasma Spray Solutions?

- 8 How to Choose the Right Thermal Spray Company in TX for Your Project