Manufacturing and other industrial works in itself are highly precise and intricate in their own rights. CNC machining services only adds to the level of accuracy and perfection that is required in these works.

In this article, we will explore what CNC machining is and how it works, and some of the reasons you may want to consider CNC machining services for your next project.

What Is CNC machining services?

CNC stands for Computer Numerical Control. CNC machining services is a manufacturing process that uses computer-controlled machine tools to create precision parts and components.

We will discuss the process in more detail later, but essentially, CNC machining services involves using a computer to control the movement of the machine tool. This allows for very precise cuts and shapes to be made in the material.

CNC machining services can be used to work with a variety of materials, including metals, plastics, and composites.

SUMMARY

Computer Numerical Control (CNC) machining is a manufacturing process in which pre-programmed computer software dictates the movement of factory tools and machinery.

How Does CNC Machining Work?

The CNC machining services services process begins with a CAD (Computer-Aided Design) file. The CAD file contains the technical drawings and instructions for the part or component to be manufactured.

The CAD file is then converted using a Computer-Aided Manufacturing (CAM) program to create the G-Code. This is the code that will be used to control the tool and create the CNC machined parts.

Other code generators can be used to create CNC programs, such as CNC-specific languages like CNC Simplified or CNC Syntax Editor. However, G-Code is the most common.

Once the code is created, it is loaded into the CNC machining services. The machine then uses the code to guide the cutting tool to create the required shape or component.

CNC Machining Materials

As we mentioned earlier, CNC machining services can be used to work with a variety of materials. Some of the most common materials that are machined using CNC technology include:

- Metals: aluminum, brass, bronze, copper, stainless steel

- Plastics: acrylic, polycarbonate, polystyrene, PVC

- Composites: carbon fiber, fiberglass

What Are the Different Types of CNC Machines?

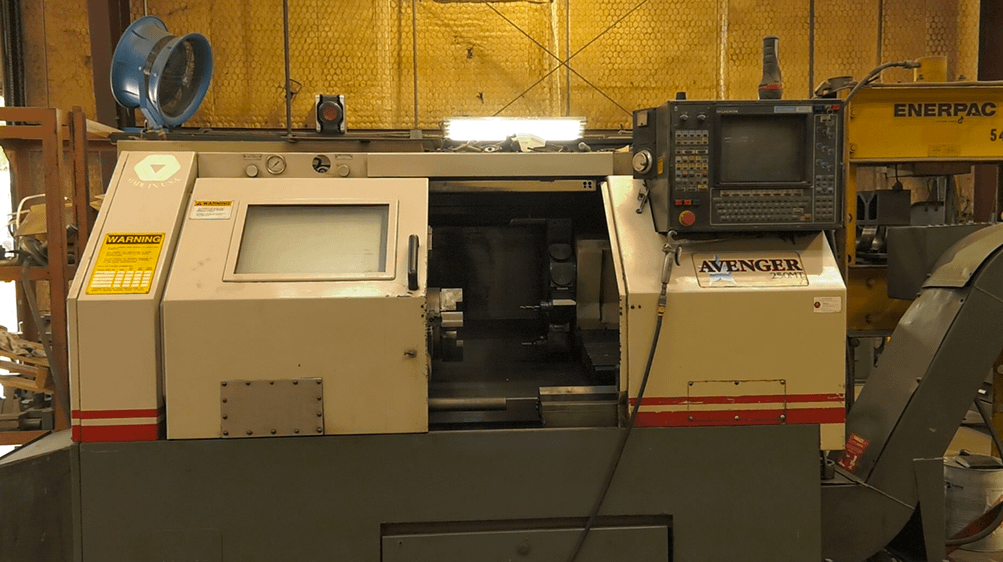

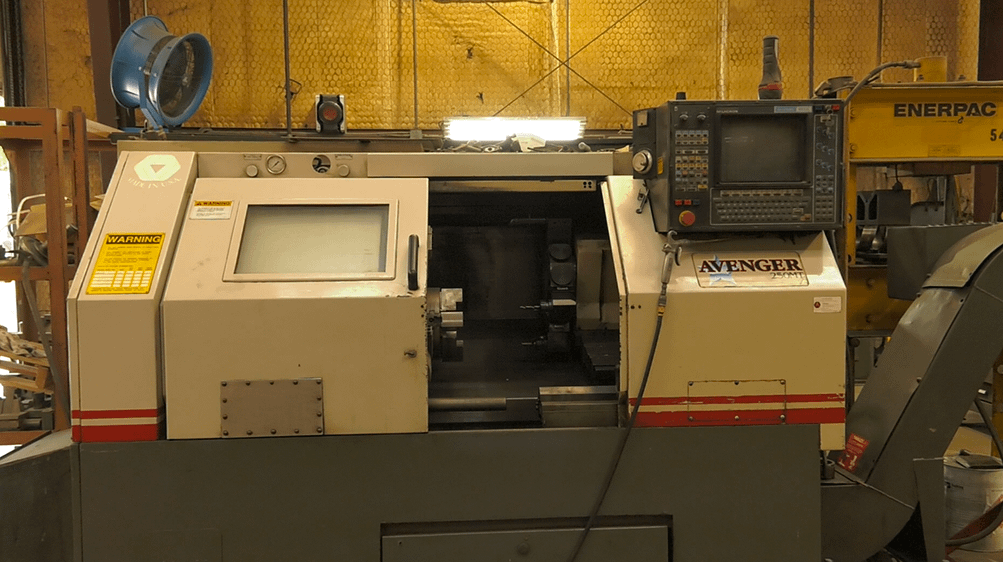

Different CNC machines services are utilized for specific kinds of CNC machining materials. CNC mills, lathes, and routers are the most common types of machines used in CNC machining:

- CNC mills: CNC mills use rotating cutting tools to remove material from the workpiece. They are typically used to create parts with more complex shapes

- CNC lathe: CNC lathe machines also use a rotating cutting tool. However, they are typically used to create cylindrical parts or those with rotationally symmetrical shapes.

- CNC routers: CNC routers are similar to CNC mills, but they are typically used for cutting softer materials like wood or plastic.

The type of CNC machine that is used will depend on the specific project requirements.

CNC Machining Services for Metal Works

For metal materials such as metal alloy and metal parts, however, CNC milling machines are most suitable, as they can create parts with very complex geometries.

The CNC machining process for metal works is slightly different from that of other materials. This is because metal is a harder material, and so the cutting tools need to be able to withstand higher levels of force and heat.

CNC Machining Services for Plastics and Composites

For CNC machining services projects that utilize plastic and composite materials, CNC routers are the most common type of machine used.

CNC routers can create parts with very intricate designs and shapes. They can also be used to create parts with smooth finishes.

The CNC machining process for plastics and composites is similar to that of other materials. However, there are some important differences to keep in mind.

For example, plastics and composites are softer materials than metals. This means that the cutting tools need to be sharpened more frequently. In addition, the cutting speed needs to be slower to avoid damaging the material.

CNC Machining Services for Wood

Wood is another common material used in CNC machining. Like plastics and composites, wood is a softer material, which means that CNC routers are typically used for CNC machining projects that utilize wood.

The CNC machining process for wood is similar to that of plastics and composites. However, since wood is typically a lighter material, the cutting speed can be faster.

In addition, wood is a porous material, which means that it can absorb moisture. This moisture can cause the wood to swell and warp. To prevent this from happening, it is important to use a CNC router that has been designed specifically for machining wood; wear and corrosion resistance are important considerations when machining wood materials.

CNC Machining Applications

CNC machining services can be used in numerous applications and industries. Some of the most common applications for CNC machining include:

- Automotive: CNC machining is commonly used in the automotive industry to manufacture parts like engine blocks, transmission housing, and suspension components.

- Aerospace: The aerospace industry relies heavily on CNC machining to create critical production parts like turbine blades and fuselage sections.

- Electrical: CNC machining is also used to create electrical components like circuit boards and encoders.

- Industrial automation: CNC machining is used in industrial automation to create parts like linear actuators and servo motors.

- Manufacturing: CNC machining is also used extensively in the manufacturing industry for the mass production of parts like gears, valves, and bearings.

- Medical: CNC machining is often used to create medical implants and prosthetics. It is also used to create surgical instruments and other medical devices.

What Are the Benefits of CNC Machining?

There are many reasons why CNC machining services has become such a popular manufacturing process. Some of the main benefits of CNC machining include:

Easy Product Replication

CNC machining is ideal for mass production as it can quickly and easily replicate parts and components. Additionally, CNC machining services enables rapid prototyping, which is perfect for product testing and development.

Creates Pieces the Human Hand Can’t

CNC machining is a very precise process that can produce parts and components with very tight tolerances and with laser-sharp accuracy. This is because the machines are controlled by computers, which can maintain consistent accuracy and precision.

Limited Human Supervision

CNC systems can be left to operate unattended for long periods of time. This is because they are highly automated and require very little human supervision.

Greater Design Flexibility

CNC machining also offers greater design flexibility than traditional manufacturing processes as it can create parts with very complex geometries.

Improved Surface Finish

CNC machining can also create parts with a very smooth and polished surface finish. This is because the cutting tools used in CNC machining can create very fine and detailed cuts.

How to Reduce CNC Machining Costs for Your Projects

The costs of CNC machining services can vary depending on a number of factors, including the type of machine used, the complexity of the part or component being machined, and the quantity being produced.

To help reduce the costs of your CNC machining projects, here are a few tips:

1. Use CNC Machining for Low-Volume Production Runs

1. Use CNC Machining for Low-Volume Production Runs

If you only require a small number of custom-machined parts or components, CNC machining can be a great option. This is because CNC machines are generally more expensive to purchase than traditional manufacturing equipment.

2. Use Simple Geometries and Materials

Complex geometries can be more expensive to create than simple geometries. This is because they require more time and effort to produce. If cost is a concern, stick to simpler designs.

Additionally, the fewer the materials, the lower the cost. So, if you can create a part or component with only one material, that will generally be more cost-effective than using several.

3. Work with a Reputable CNC Machine Shop

Working with professional CNC machine shops like Wearmaster can help you save money on your CNC machining projects. This is because they have the experience and expertise to produce high-quality parts and components at a lower cost.

Why Choose Wearmaster for Custom CNC Machining?

CNC machining is a specialized process that requires the use of complex machinery and a great deal of experience and expertise. Wearmaster has been serving the southwestern region of the United States since 1983, and our team of experienced CNC machinists is some of the best in the business.

In addition to our experience, we also offer a number of other advantages, including:

Competitive Pricing

We offer competitive yet reasonable and affordable pricing on all our CNC machining services. We also offer discounts for larger projects and cater to businesses of all sizes.

Quality Control

We have a rigorous quality control process in place to ensure that all CNC parts and components meet the highest standards of quality.

Fast Turnaround Times

We understand that time is often of the essence when it comes to CNC machining projects. With Wearmaster, you can rest assured that your project will be completed on time and within budget.

Full-Service Capabilities

Wearmaster offers a complete range of CNC machining services, from design and engineering to production and assembly. We can also provide a number of value-added services, such as thermal spraying and HVOF coating.

If you’re looking for a CNC machine shop near Dallas or around the Texas area, Wearmaster is here to serve you. Contact us today to learn more about our CNC machining services or to request a free quote for your next project.

CNC Machining FAQs

HOW MUCH DOES CNC MACHINING COST?

As we mentioned, the cost of CNC machining can vary depending on several factors, including the type of machine used, the complexity of the CNC part, the number of materials used, and the quantity being produced.

To get a better idea of how much your CNC machining project will cost, we recommend getting a quote from a CNC machine shop like Wearmaster.

WHAT TYPES OF THREADING OPTIONS ARE AVAILABLE?

There are a variety of threading options available for CNC parts, including external and internal threads. The type of threading option that’s best for your project will depend on the application and the type of material being used.

WHAT IS THE MAXIMUM PART SIZE FOR CNC MACHINING?

The maximum part size that can be CNC machined will depend on the type of machine being used. The largest machines can accommodate workpieces measuring up to 100 inches in length and width.

Table of Contents

- 1 What Is CNC machining services?

- 2 How Does CNC Machining Work?

- 3 CNC Machining Materials

- 4 What Are the Different Types of CNC Machines?

- 5 CNC Machining Applications

- 6 What Are the Benefits of CNC Machining?

- 7 How to Reduce CNC Machining Costs for Your Projects

- 8 Why Choose Wearmaster for Custom CNC Machining?

- 9 CNC Machining FAQs

1. Use CNC Machining for Low-Volume Production Runs

1. Use CNC Machining for Low-Volume Production Runs