Learn the Basics of CNC Lathe Machining

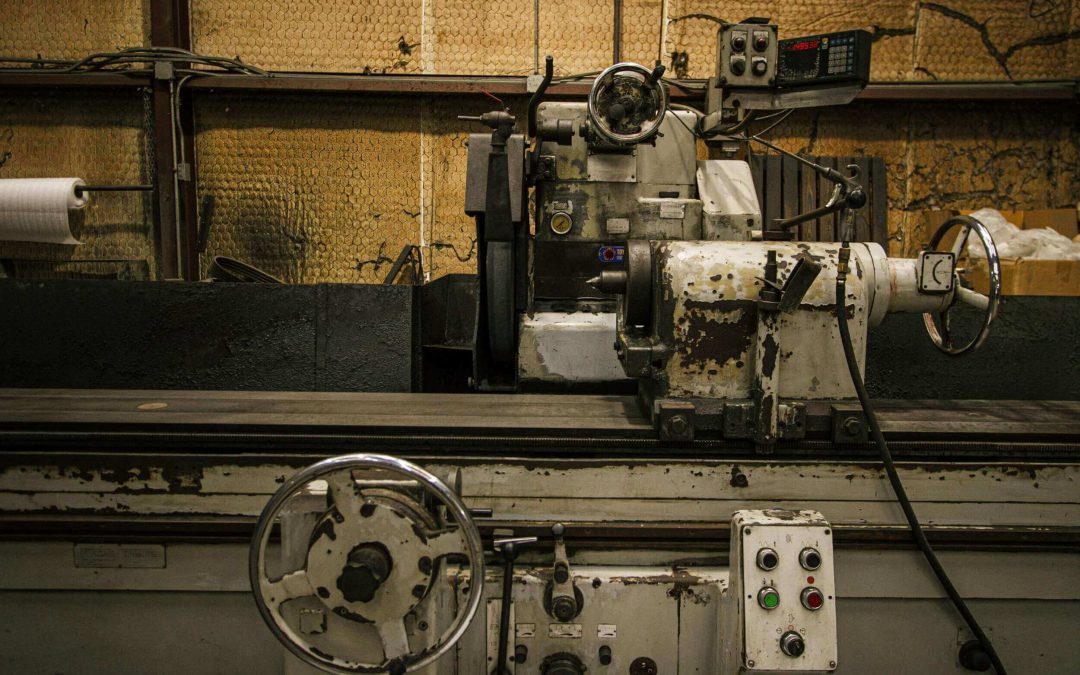

Computer Numerical Control or CNC machines are automated cutting tools that are used to create parts and components with extreme precision. And among all the CNC machining processes, CNC lathe machining is one of the most commonly used.

In this article, we will be discussing everything you need to know about CNC lathe machining and why it could be ideal for your manufacturing needs.

Introduction to CNC Lathes

CNC lathes are a specific type of CNC machining that is used to create cylindrical parts or complex components that require precise round shapes. This process is also sometimes referred to as CNC turning.

CNC lathe machines typically consist of three main parts: the spindle, the toolholder, and the turret:

- The spindle is the part of the CNC lathe machine that holds and rotates the workpiece. The spindle motor is usually located underneath the spindle, and the spindle bores are where the workpiece is inserted.

- The toolholder is the part of the CNC lathe machine that holds and secures the cutting tools. The most common type of toolholder is the turret, which is a rotating disk that holds multiple cutting tools.

- The upper and lower turret, also sometimes called a headstock, is the part of the machine that holds and indexes the cutting tools.

CNC lathe machining is a subtractive manufacturing process, which means that material is removed from the workpiece to create the desired shape.

The three most common ways to remove material during CNC lathe machining are turning, boring, and drilling:

- Turning is the process of removing material from the exterior of a workpiece to create a cylindrical shape.

- Boring is the process of removing material from the interior of a workpiece to enlarge a hole.

- Drilling is the process of creating a hole in a workpiece.

How Does the CNC Lathe Machining Process Work?

As an overview of the overall CNC machining process, it begins with precise design instructions that are fed into the CNC machine.

These design instructions are then used to generate a computer program, which tells the CNC machine how to operate.

During CNC lathe machining, the workpiece is mounted on the rotating spindle of the CNC lathe machine. The workpiece is then rotated at a high speed and the cutting tools are fed into the rotating workpiece.

This is why CNC lathes are often called CNC turning: because the workpiece is turned on its axis as it is being machined.

The cutting tools are fed into the workpiece at different angles and depths to create the desired shape. This part of the process also involves CNC drilling and turning.

The process continues until the cutting tools have reached the desired depth or the correct size. Once done, surface finishing techniques can be used to improve the appearance or function of the workpiece.

Some common surface finishing techniques that are used in CNC lathe machining include anodizing, painting, plating, and heat treating.

Linear axes are also often used in CNC lathe machining to create more complex shapes. The linear axes can be programmed to move the cutting tools in a straight line, which allows for the creation of non-cylindrical shapes.

Benefits of CNC Lathes

CNC lathes offer a number of advantages over traditional machining processes:

- Precision: CNC lathes can create very precise and accurate parts and components.

- Repeatability: CNC lathes can produce parts that are identical to each other.

- Flexibility: CNC lathes can be used to create a wide variety of shapes and sizes.

- Speed: CNC lathes can operate at high speeds to produce parts quickly.

- Easy to use: CNC lathes are easy to operate and require minimal training.

Applications of CNC Lathes

CNC lathe machining is a very versatile manufacturing process and can be used to create a wide variety of industries and applications. Some of the most common ones include:

- Medical: CNC lathes are often used to create medical devices and implants.

- Automotive: Lathes are used to create a variety of automotive parts, including engine components, suspension parts, and transmission parts.

- Mining: Lathes are also used to create mining equipment, such as drill bits and mining trucks.

- Manufacturing: Lathes are most often used in the manufacturing of a variety of products, including furniture, appliances, and electronics.

- Automation Solutions: CNC lathes can be utilized to create robotic parts and components.

Types of CNC Machine Tools

There are many different types of CNC machine tools, but the most common ones include:

CNC Milling Machines

CNC Milling Machines

Milling machines are the most common type of CNC machine. This type of CNC machine is usually used to create large and complex parts, and for materials made of wood, metal, or plastic. Helical milling operations and face milling operations are the two most common types of CNC milling.

CNC Turning Center or CNC Lathe Machines

Turning centers are CNC machines that are used to create cylindrical parts. The most common type of turning center is the lathe machine. These machines can be used to create parts made of wood, metal, or plastic.

CNC Router Machines

Router machines are CNC machines that are used to create three-dimensional shapes. While these machines can be used for a variety of materials, it is most indicated for woodwork.

CNC Plasma Cutting Machines

Plasma cutting machines are CNC machines that are used to cut metal. These machines use a plasma torch to cut through metal and are often used in the automotive and aerospace industries.

CNC Drilling and Screw Machines

Drilling machines are CNC machines that are used to create holes, while screw machines are used to create screws. These machines can be used for a variety of materials, including wood, metal, and plastic.

CNC Grinders

Grinders are CNC machines that are used to remove material from a workpiece. This type of machine is most often used for metals.

Types of CNC Lathe Machines

CNC lathes are available in a wide variety of sizes, shapes, and styles. The most common types of CNC lathe machines include:

Manual CNC Lathes

Manual CNC lathes are the simplest type of CNC lathe machine. These machines are operated manually by the user and do not require any computer numerical control.

CNC Swiss Lathe Machines

Swiss lathe machines are CNC lathes that are used to create small and intricate parts. These machines are often used in the medical and aerospace industries.

CNC Turret Lathe Machines

Turret lathe machines are CNC lathes that have a turret that can hold multiple tools. These machines are often used for mass production.

CNC Vertical and Horizontal Lathe Machines

Vertical lathe machines, as the term suggests, are CNC lathes that have a vertical spindle, while horizontal lathe machines have a horizontal lathe. These machines are often used for large and heavy workpieces.

How the Parts of a CNC Lathe Machine Works

We briefly mentioned earlier some of the parts of a CNC lathe machine, but we will go into deeper detail in this subsection.

When a CNC lathe machine is in operation, the rotating spindle will turn the workpiece while the cutting tool is fed into it. The speed and depth of the cut can be controlled by the user and is measured by the computer numerical control.

The tool turret is used to hold the cutting tool in place and can be rotated to different positions. Different axes points are created by the tool turret, which allows for different types of cuts to be made:

- Y axis: The Y axis is the horizontal axis and is perpendicular to the X axis.

- X axis: The X axis is the vertical axis and is perpendicular to the Y axis.

- Z axis: The Z axis is the axis that is perpendicular to both the X and Y axes.

- C axis: The C axis is the rotational axis and is perpendicular to all three of the other axes.

The machine can either be a 2-axis CNC lathe or a 3-axis CNC lathe. A 2-axis CNC lathe machine will only have an X and Z axis, while a 3-axis machine will have an X, Y, and Z axis.

The tailstock is the third main part of a CNC lathe machine and is used to support the workpiece. The tailstock can be moved along the X axis and is often used for drilling holes.

The lathe machine process continues until the desired shape or size of the workpiece is achieved. After the CNC part is completed, it will need to be heat treated to relieve any stress that has been placed on it during the machining process.

How to Choose the Best CNC Lathe Machine

When choosing a CNC lathe machine, there are a few factors that you need to consider:

- The size of the workpiece: The size of the workpiece will determine the size of the CNC lathe machine that you need.

- The type of material: The type of material that you will be working with will determine the type of CNC lathe machine that’s most suitable.

- The complexity of the part: The complexity of the part will also determine what kind of machine is needed, how long the process will take, etc.

For example, if you are working with small and intricate parts, you will need a CNC Swiss lathe machine. If you are working with large and heavy workpieces, you will need a CNC vertical or horizontal lathe machine.

If you need more guidance in choosing the best CNC lathe machine for your needs, you can consult with professional CNC machine shops such as Wearmaster.

Wearmaster for Your CNC Lathe Machining Needs

If you’re based in Kennedale, TX, and other surrounding areas, Wearmaster is the company you can count on for your CNC lathe machining needs.

We have been in the industry since 1983, and we take pride in our top-notch CNC lathe machining services. We use state-of-the-art machines, and our team of experts is always ready to assist you.

We also offer a wide range of other machining services, including CNC milling, CNC turning, CNC Swiss machining, and more.

To learn more about our services, please don’t hesitate to contact us today!

CNC Machining FAQs

WHAT CAN A CNC LATHE MAKE?

CNC lathes can be used to create small and intricate parts. Some examples include medical screws, aerospace components, and more.

IS CNC LATHE HARD TO LEARN?

CNC machining in itself requires specialized training, so it is not something that you can learn overnight. However, once you have the proper training, CNC lathe machining is not difficult to master.

HOW MUCH DOES CNC LATHE MACHINING COST?

The cost of CNC lathe machining will depend on the size and complexity of the parts that you need to be machined. To get a more accurate estimate, please contact a professional CNC machine shop such as Wearmaster for a free quote.

ARE LATHE AND CNC THE SAME?

CNC is a type of machine, while lathe is a type of operation that can be performed on a CNC machine. In other words, all CNC lathes are CNC machines, but not all CNC machines are lathes.

WHICH IS BETTER: CNC LATHE OR CNC MILLING?

There is no clear answer as to which one is better. It really depends on the specific application and requirement. In general, CNC lathes are better for small and intricate parts, while CNC mills are better for large and heavy parts. CNC lathes are also more appropriate for materials like wood, while CNC mills are more appropriate for metals.

WHAT IS THE DIFFERENCE BETWEEN CNC TURNING MACHINES AND CNC LATHE MACHINES?

CNC turning machines are designed for precision turning applications. On the other hand, CNC lathe machines are designed for both turning and milling applications. However, both types of machines can be used for lathe operations.

HOW MUCH FASTER IS A CNC MACHINE?

CNC machines can be up to 100 times faster than manual machines. Generally, CNC machines can perform operations at a speed of between 10 and 1000rpm.

Table of Contents

- 1 Introduction to CNC Lathes

- 2 How Does the CNC Lathe Machining Process Work?

- 3 Benefits of CNC Lathes

- 4 Applications of CNC Lathes

- 5 Types of CNC Machine Tools

- 6 Types of CNC Lathe Machines

- 7 How the Parts of a CNC Lathe Machine Works

- 8 How to Choose the Best CNC Lathe Machine

- 9 Wearmaster for Your CNC Lathe Machining Needs

- 10 CNC Machining FAQs

- 10.0.0.1 WHAT CAN A CNC LATHE MAKE?

- 10.0.0.2 IS CNC LATHE HARD TO LEARN?

- 10.0.0.3 HOW MUCH DOES CNC LATHE MACHINING COST?

- 10.0.0.4 ARE LATHE AND CNC THE SAME?

- 10.0.0.5 WHICH IS BETTER: CNC LATHE OR CNC MILLING?

- 10.0.0.6 WHAT IS THE DIFFERENCE BETWEEN CNC TURNING MACHINES AND CNC LATHE MACHINES?

- 10.0.0.7 HOW MUCH FASTER IS A CNC MACHINE?

- 10.1 Related posts:

- 11 Metal Spray Coating

- 12 Why Direct to Metal Coatings Are Important

- 13 Plasma Spray Coating