Why Direct to Metal Coatings Are Important

There are many types of spray metal coatings, and each of them has its own advantages and disadvantages. The kind of coating that’s most appropriate for your project will highly depend on the kind of material you’re working on.

For metal surfaces, in particular, a direct-to-metal coating spray is ideal. DTM coatings are ideal for metal surfaces because they provide superior adhesion and corrosion resistance compared to traditional paint systems.

If you’re considering metal spray coating for your metal surfaces, it’s important to know how it works to ensure that you get the best results.

What Is Metal Coating?

A metal coating spray is a kind of metal finish applied to metal surfaces in order to enhance their appearance and protect them from corrosion.

It’s usually composed of metal powder, metal particles, or metal alloy particles suspended in a binding agent. When applied to metal surfaces using a spray gun, the metal coating bonds with the metal surface and forms a protective film.

What Is the Purpose of Metal Coating?

As we mentioned, metal spray coating serves as a protective layer for metal surfaces. It prevents corrosion by blocking out moisture and other environmental elements that can cause damage to metal surfaces.

Additionally, metal coatings also provide metal surfaces with a more aesthetically-pleasing finish. By choosing metal coatings with various textures, tones, and shades, you can create metal surfaces with a unique, customized look.

Where Are Metal Coatings Used?

Metal coatings are commonly used in metal machine shop services and metal fabrication projects. They can be used with metal objects of all sizes, including metal fixtures, automotive parts, and metal tools.

Thermal spraying metal coatings are also popular in metal fabrication. This spraying method is used to apply metal spray coating, such as chrome and zinc-based coatings, to metal surfaces.

It’s also used in metal fabrication projects such as metal doors and window frames, metal furniture, metal signs, metal sculptures, metal railing, metal pipe and tube, metal cladding, metal decking, and metal structural components.

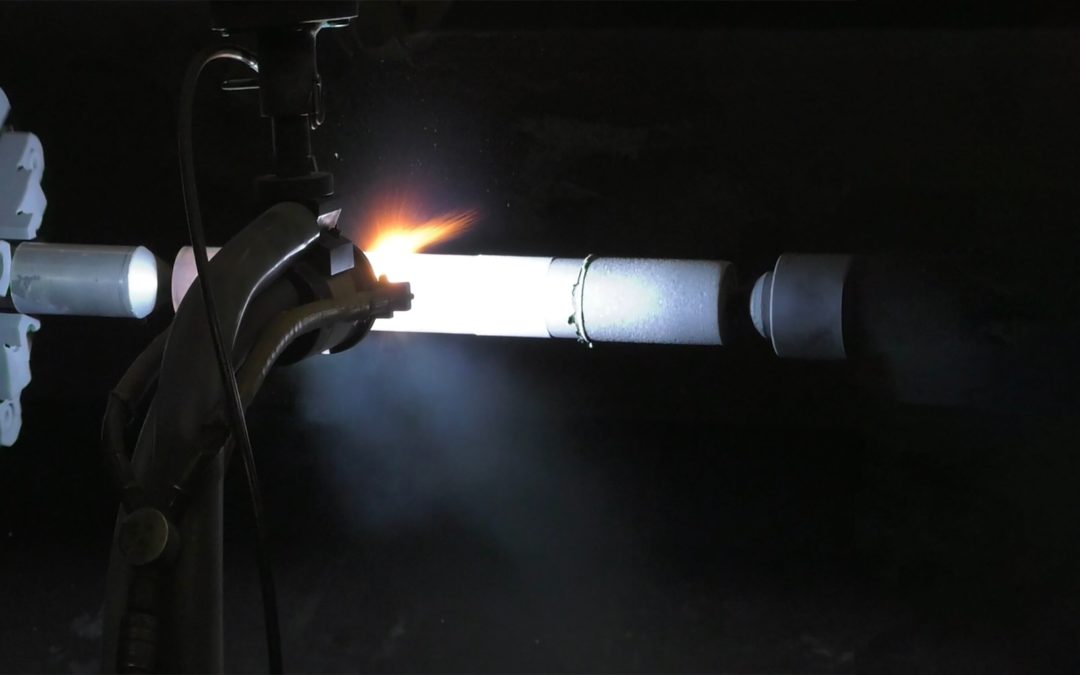

What Is the Metal Spray Coating Process?

The metal spraying process involves heating metal particles and propelling them with a high-pressure stream of air or gas onto a metal surface. The metal particles then melt and adhere to the metal surface, forming a protective metal coating.

Substrate materials such as metal must be cleaned and prepped before metal spray coating. This helps to ensure that the metal particles adhere properly to the metal surface for maximum protection.

Additionally, metal machine shop services often use a rotating spray gun to ensure even and uniform metal coating coverage.

Metal Coating Types

There are many metal coating types available, and the coating processes for each metal coating type vary. Common metal coatings include:

Metalizing

Metal particles are melted and sprayed onto metal surfaces

Thermal spraying

Metal particles, metal powder, and metal alloys are melted and sprayed onto metal surfaces

Metal plating

Metal particles are deposited on metal surfaces through electroplating

Metal powder coating

Metal powder is applied to metal surfaces through electrostatic deposition.

Metal rolling

Metal particles are heated and applied to metal surfaces through a rolling process

Metal brush-on coating

Metal particles are applied to metal surfaces using brushes.

Metal wax-based coating

Metal particles are suspended in a wax-based resin and applied to metal surfaces

Wearmaster Coatings Address Many Concerns that Go into a Coating Project

Coating processes of substrate materials require expertise and the right tools in order to achieve the best results. If you need metal machine shop services in Texas, Wearmaster can provide thermal spray metal coating solutions that are sure to meet your metal fabrication needs.

With Wearmaster, you’ll benefit from metal spray coating materials that are designed to last and protect metal surfaces, and more:

1. Rapid Productivity

At Wearmaster, metal coatings are applied quickly and accurately using highly efficient thermal spraying techniques. We ensure that our turnaround time is minimal and that metal surfaces are properly coated in order to prevent corrosion and wear.

2. Superior Adhesion

Our metal coating processes ensure that metal particles adhere properly to metal surfaces for strong durability and protection. Our metal coatings also protect against abrasion and impact, providing metal surfaces with long-term protection.

3. Corrosion Protection and Water Resistance

We also ensure that metal surfaces are protected against corrosion and water damage. With our advanced thermal spraying process, our metal coatings are sure to hold up even against the harshest weather conditions.

4. Enhanced Longevity

At Wearmaster, we provide metal coatings that are designed to last. Our metal coatings are resistant to wear and tear, allowing metal surfaces to maintain their strength and integrity for years to come.

5. Relative Ease of Application

We use the latest equipment and techniques for direct-to-metal thermal spray coating to ensure that all our projects are done with relative ease and accuracy. This helps to reduce the time and cost of metal fabrication projects.

6. Environmental Sustainability

Lastly, metal coating spray materials used at Wearmaster are safe for the environment. Our metal coatings are RoHS-compliant and free of heavy metals, helping to reduce metal fabrication waste and ensure that metal fabrication projects are sustainable.

Taking Direct-to-Metal Coatings to the Next Level

With metal machine shop services from Wearmaster, you can trust that the metal coating process will be done correctly and efficiently.

Our metal coating spray materials are of the highest quality and designed to provide maximum protection. We also offer metal fabrication services in Texas, metal plating, metal powder coating, metal rolling, and metal brush-on coatings.

Thermal Spray Coating Texas

If you’re looking for a reputable machine shop service in Texas, Wearmaster is here for you.

We offer metal thermal spray coating solutions that are sure to give metal surfaces the protection they need. Contact us today to get a free quote!

Table of Contents

- 1 What Is Metal Coating?

- 2 What Is the Purpose of Metal Coating?

- 3 Where Are Metal Coatings Used?

- 4 What Is the Metal Spray Coating Process?

- 5 Metal Coating Types

- 6 Wearmaster Coatings Address Many Concerns that Go into a Coating Project

- 7 Taking Direct-to-Metal Coatings to the Next Level

- 8 Thermal Spray Coating Texas